| About Us | Charcoal | Products | Lambiotte technology | Investments | Contacts |

Investment in the project development for complex wood processing is highly profitable; it carries a low risk and excellent economic indicators:

-

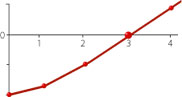

The project will pay for itself in 3 years

- The internal rate of return

Information regarding the project of developing the production unit for complex wood processing according to the LAMBIOTTE technology,

preparation of the business plan and stages of its implementation is available by the phone

+ 371 37129239323,

or by sending an application.

If you already are a producer of charcoal or just plan to start the production, we invite you to learn more about the advantages of Belgian charcoal production technology – LAMBIOTTE. Today, this technology is leading among the most highly efficient technologies in the world.

The LAMBIOTTE technological process in comparison to the well-known methods of wood thermal treatment has a number of advantages:

1. High Productivity and Power Efficiency.

This method is distinguished by the fact that only the pyroligneous vapours are burnt, exclusive of the wood and the charcoal, which

increases the production capacities by more then 2 times.

All the existing technologies are based on the heating by the external heat carrier, but the process of the LAMBIOTTE technology is

autothermal.

The by-product of the LAMBIOTTE technology is the combustible gas, which is suitable for the generation of electric power and thermal

energy.

According to the energetic balance up to 50% of the combustion heat of the source wood is contained in the coal and up to 50% – in the

combustible gas. That is why it is necessary to have large consumers of the thermal energy for successful project implementation with

relatively even year-round load. The energy efficiency is 96%.

At the expense of the effect of the complex treatment and production of several products – charcoal and combustible gas, the realization of

the product, which is more expensive – charcoal – can compensate the majority of the costs. That is why the prime cost of the produced thermal

energy reduces and actually it is beyond comparison if we compare it with energy generation from any other type of fuel.

2. Ecological Safety and Waste Reduction.

All the organic compounds of the LAMBIOTTE technology are decomposed and gasified inside the device. The combustible gas is burned and

supplied to the boiler-utiliser without extra treatment. During its burning the specific emissions of NOx, SOx, CO and

dust are lower than those of the coal boiler room or the heat station, lower than the applicable normative values and a hundred times lower

than in the by-product-coking production.

The LAMBIOTTE technology does not use water for coke quenching and condensation of the products of thermal decomposition is not done,

therefore, there are no waste water produced from this process.

In contrast to all the existing technologies, this process has no discharge of the gaseous heat carrier in the atmosphere and that is why

there is no need to arrange for additional systems for gas cleaning.

3. Automatic Production

The automatic regulation of the plant allows for a drastic reduction of the workforce, compared to traditional production methods. The control software is provided with real-time interactive control and regulation system.

4. Simplicity of the Equipment Execution and Single-stage Process.

The stages of drying, pyrolysis, thermal decomposition of volatile ingredients and cooling of charcoal are combined in one device. The specific capital expenditure is lower than in other technologies.

5. Reliability of the Equipment.

The SIFIC/CISR retort is entirely heat-insulated, thus avoiding the condensation of corrosive liquids and ensuring a long life to the installation.

The LAMBIOTTE technology allows for a considerable reduction of the dependence on the energy generation of one type of fuel. The simplicity of transportation and availability of feedstock – wood – allow considerable lowering of the risks which are caused by the economic and political events.

SPECIFICATION OF THE INSTALLATION

| Annual charcoal production: | 2,000 - 6,000 tonnes, depending on their dimensions. |

|

Annual wood requirement: (The wood of any quality and type) |

8,000 – 24,000 tonnes. - provided the wood has a water content of 25 % calculated on the total weight. - the length of the pieces should not exceed 33 cm. - the cross section of the wood pieces should be below 10 cm |

| Charcoal productivity: | 245 kg per ton of wood. |

| Installed power: | 120 to 150 kW. |

| Power consumption: | 40 to 60 kW. |

| Approximate net/gross weight: | 95/100 tonnes. |

| Approximate area: | 600 m2. |

| Man-power: | 14 to 17 people |

| Average life time: | 15 years |