| About Us | Charcoal | Products | Lambiotte technology | Investments | Contacts |

The charcoal is excellent fuel for everyday use such as in char grills, fireplaces and barbecues. Thanks to the low level of the smoke creation and the high heating value, the present type of fuel is an ideal solution for cooking on the open flame.

SiO2 + C = Si + CO2

C + 2S = CS2

Approximately 10 million tons of charcoal is produced annually in the world. The time for new technologies, new equipment, experience and

knowledge has come, which will help successfully to introduce more up-to-date technologies for charcoal production and to find the right way

to use it.

There are several methods of charcoal production: the earth kiln, the metallic kiln and the industrial kiln.

An important advantage of the industrial kiln is the possibility of using the energy of the surplus pyroligneous vapours.

The industrial kiln, with a production volume of 2,000 tons of charcoal a year releases approximately 1,000,000 kcal/h, i.e., 2.4 TOE

(ton of oil equivalent) of additional energy per day.

This energy could be used to supply small local enterprise and/or living houses. Meanwhile, there is no problem with air pollution, which is

otherwise unavoidable when using the non-professional kiln.

Modern processes of coal production, such as LAMBIOTTE, allow for the use of heat generated from the surplus pyroligneous vapours. Thus the total productivity of carbonization represents a pure profit especially in regions having difficulties in providing for the demand in energy.

The charcoal is excellent fuel for everyday use such as in char grills, fireplaces and barbecues. Thanks to the low level of the smoke creation and the high heating value, the present type of fuel is an ideal solution for cooking on the open flame.

Application of Charcoal in the Industry

The industrial use of charcoal has a great market potential provided that the equipment allowing for the production charcoal of the required quality is used.

The coal is actively used in the metal, pharmaceutical and polymer industry; it is an excellent thermal insulator, which fact has kick-started its application in the construction field. Furthermore, the well known absorptive properties of the coal allow for its application in a variety of treatment complexes, as could be expected.

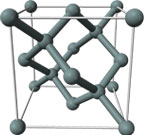

1. Production of Silicon

The charcoal produced by a LAMBIOTTE SIFIC/CISR retort is an excellent raw material for the production of crystalline silicon.

In the expanding Silicium industry charcoal is used as reducing agent. Its low ash content, its composition and above all the absence of aluminium are appreciated quality factors for the production of ferro-alloys.

The elementary silicon is recovered by carbon in accordance with the equation

| SiO2 | + | C | = | Si | + | CO2(gas) |

The reaction of recovery is implemented in the melt at temperature of 1700°С - 2000°С.

The coal has to be reactive for this reaction. For instance, anthracite is not reactive, while charcoal, on the other hand, has shown itself

to be an excellent reagent.

The demands regarding the temper of fixed carbon are the same like those of quality fuel; still, the demands regarding the ash content and

the granulometry are stricter here. The coal, which is received using LAMBIOTTE technology, completely corresponds to all the necessary

parameters for silicon production.

Several large silicon production companies were founded in the first decade of the 21st century. Their demands on the quality of the coal are high and they are determined by production regulations. As coal demand increases, the non-professional installations can no longer manage such volumes. The amount necessary for silicon producers can be reached only through the use of competently organised, sufficiently large-scale and ecological production. One such enterprise is located in Norway (“ELKEM”) and it consumes 60 thousand tons of coal a year for silicon production, where coal has been produced by the LAMBIOTTE retorts.

2. Production of Carbon Bisulphide

Carbon bisulphide is generated in the result of molten sulphur and hot charcoal interaction.

| C | + | 2S | = | CS2 |

| Solid | Fluid | Vapour |

The production process has uninterrupted regime; the coal is loaded into the reactor in a heated form in order to keep temperature from

falling during the sulphur melt. 0.16 tons of carbon are required per sulphur ton.

Hydrogen in the charcoal leads to the formation of H2S admixtures. For this reason, the raw material with the smallest quantity of

volatile substances is required in this field. Coal raw materials with reduced ash content are also necessary. The small particles are a

special problem for the production process. The friable coal, which is produced from soft wood and damp wood, contains a large amount of them.

3. Metal Casting Industry

This industry has a large demand for carbon produced by means of wood carbonization.

A great amount of fixed carbon is required. The LAMBIOTTE retorts can produce coal, which contains up to 95% of fixed carbon, during one cycle. The increased content of carbon is accompanied by the decreased amount of volatile substances.